- Academics

- Admissions & Enrollment Services

- Research

- Academic & Creative Spaces

- Strategic Partnerships

- Our Impact

- Student Affairs

- Campus & Community

VCUarts Qatar Puts 3D Technology to Use to Print Cameras in Face of Pandemic Challenges

October 11, 2020

Categories

VCUarts Qatar Puts 3D Technology to Use to Print Cameras in Face of Pandemic Challenges

When educational institutions in the country reopened for the new academic year, it was apparent that the delivery of certain essential tools and resources would be delayed, due to the pandemic-induced disruptions to normal business operations.

Such delays, though, were hardly an issue for faculty and staff at VCUarts Qatar, a Qatar Foundation partner university.

When classes started for the 2020 fall semester, faculty and staff at the university’s Painting + Printmaking (PAPR) department realized that they wouldn’t be able to import enough analogue cameras for all the students in the pathway, in time for the start of the course.

Analogue (or pinhole, as it is popularly referred to) camera photography being an integral part of the PAPR curriculum – and purchasing cameras from within the country proving to be too expensive – faculty and staff did the next best thing – they made their own. Or rather, they 3D printed them.

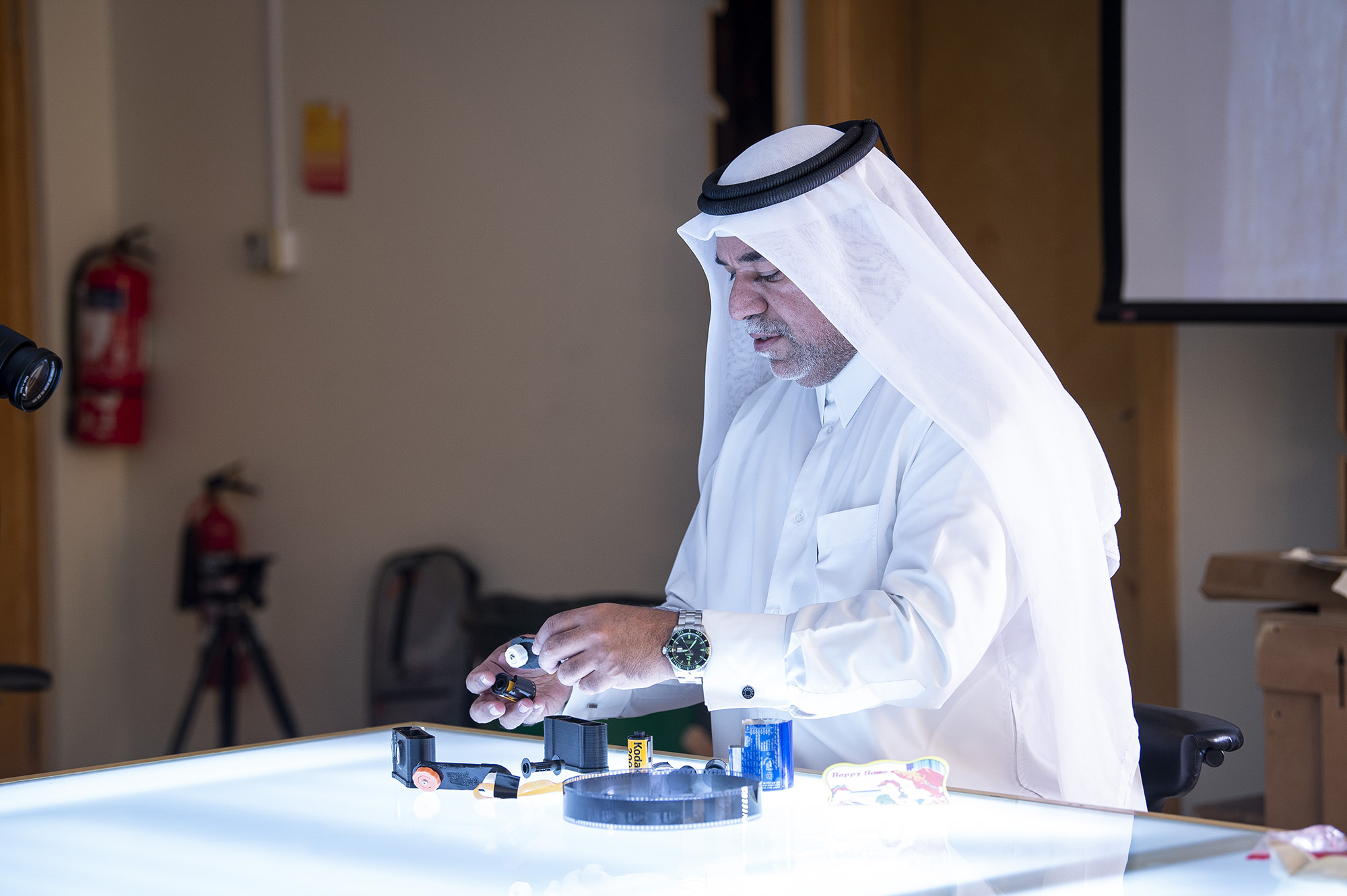

“We realized that due to the COVID-19 induced delays to business processes and shipment, we didn’t have the luxury of time to import enough analogue cameras for our students,” says Khalifa Al-Obaidli, Adjunct Instructor at VCUarts Qatar’s department of Painting + Printmaking. “And purchasing them locally was too expensive an option.

“As creatives and designers, we’re trained to look for solutions. In this specific case, that meant making our own. Online research revealed an open-source link to designs that could be 3D printed. We discussed our idea with the FabLab team who were excited about the possibility of creating analogue cameras from scratch.”

Al-Obaidli and other PAPR faculty including Aissa Deebi, Abir Zakzok and Rola Khayyat worked with VCUarts Qatar’s FabLab team to 3D-print various component models first; Saga Elkabash from the FabLab team further adapted these models to meet the specific requirements of the PAPR curriculum that includes analogue or pinhole photography.

“The beauty of analogue photography – unlike digital photography – lies in being able to observe the actual process of photo development, from shooting an image, to dark room development,” Al-Obaidli explains. “It’s a chemical process that results in an image materializing before your very eyes.

“As an instructor, I’ve seen the reaction of students as they watch the black and white outlines emerge on paper – any doubt they may have had, is replaced by wonder and joy. This is why teaching analogue photography is important in art and design. It gives practitioners a thorough understanding of the basics and history of image production.”

Chris Buchakjian, VCUarts Qatar’s Digital Fabrication Lab & Woodshop Coordinator, who was part of the team that researched and developed the camera, explained the development process further.

“PAPR faculty pointed us towards an Open Source 3D Printable camera designed by Clint O’Conner,” says Buchakjian. “With this 3D model as our starting point, we made adjustments based on the needs of the faculty. The camera is almost entirely 3D-printed. It’s a lovely design and a testament to the value of open source 3D modeling communities that collaborate to share expertise.”

The FabLab team 3D-printed seven components for each camera, with each camera taking up to seven hours to print. The timely collaboration between the two departments meant that all 20 students on the pathway have enough analogue cameras to continue their course undisrupted – with a few extra ones to spare.

All photographs by Raviv Cohen.

Video by Nic van der Bijl.